No Record Found

Latest News

Neha Kakkar grooves with `Gulabi Sadi` hitmaker Sanj...

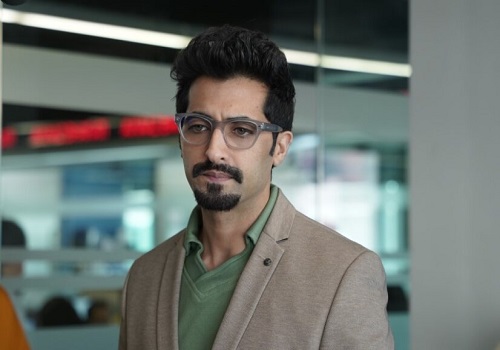

After `The Broken News 2`, Akshay Oberoi says agenda...

With IWL-2, home-and-away league in place, AIFF reco...

Arjun breaches Air Rifle world record in Olympic Sel...

Evening Roundup : A Daily Report on Bullion Energy &...

Nifty closes above 22,550, Sensex up 487 pts on anot...

Daily Market Analysis : Markets resumed up move on t...

India`s IndiGo places order for 30 Airbus A350 jets

Goa Chief Minister Pramod Sawant celebrates his birt...

Union Minister Smriti Irani participates in `Dukhdur...

Top News

News Not Found

Tag News

News Not Found

More News

News Not Found